Materials Science and Engineering researchers at North Carolina State University recently detailed their method to produce large amounts of metallic glass alloys using 3D printing. The development could lead to better efficiency in electric motors and tougher materials and structures.

Researchers at the Material Science and Engineering department at North Carolina State University have turned to 3D printing to create a means to produce bulk amounts of metallic glass alloys. Typically produced in small amounts, the material (also known as amorphous metals) is notoriously tricky to produce in any large amount.

Unlike most other metals, metallic glass alloys lack a crystalline structure. With an amorphous structure instead, they boast “exceptionally desirable properties”, says Zyanab Mahbooba, a Ph.D student at the department and first author of the research’s paper.

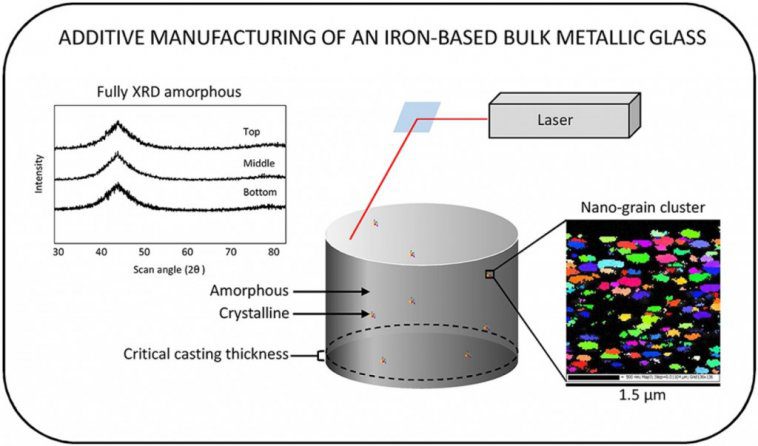

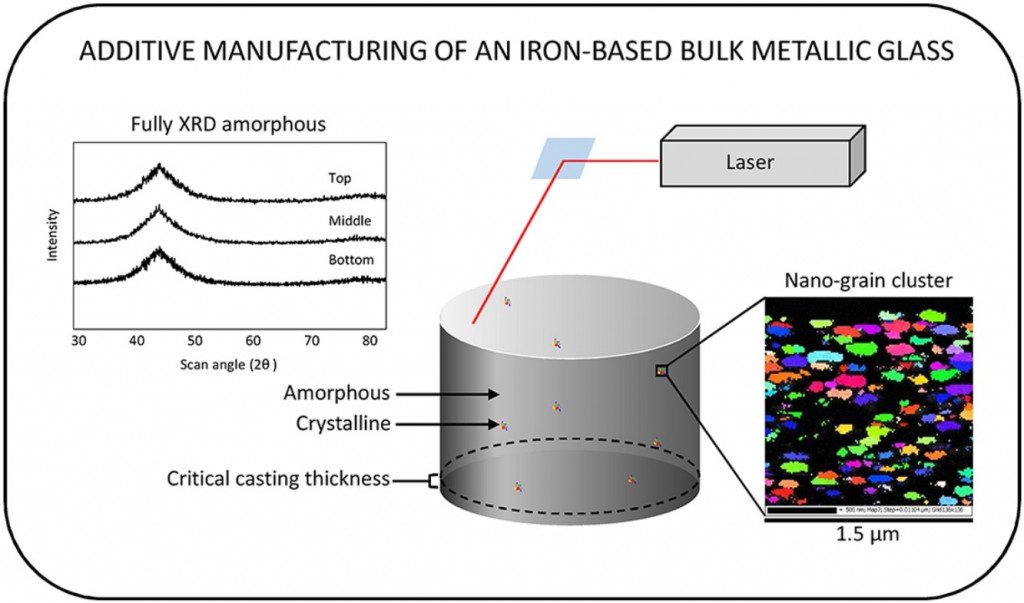

To create metallic glass alloys requires the rapid cooling of the metal as it’s produced. Because of this, traditional efforts to create it can only yield casts of the amorphous alloy only millimeters thick (up to a size known as the alloy’s critical casting thickness).

Casting Metallic Glass Alloys in Bulk with 3D Printing

The notion of using additive manufacturing technologies to create amorphous metal alloys is not a new one. Kicking around the weeds for some tens of years, Mahbooba claims this is the first published work to prove the concept. She adds: “We were able to produce an amorphous iron alloy on a scale 15 times larger than its critical casting thickness.”

Though it is not specified which machine was used, a press release describes the process of Direct Metal Laser Sintering. A bed of metal powder (in this instance, iron-based alloy) is melted by a laser. After each pass of the laser is complete the whole bed descends 20 microns and a new layer of powder is deposited on top. The laser makes another pass, sintering the metal on top of the previous layer, building up the model bit by bit.

For the metal to form with non-crystalline properties, it is crucial that it is cooled extremely quickly. The concept proven here is that the melting of the powder is in such small quantities and area at any one time, the material can cool sufficiently fast enough to contain the desired amorphous structure.

Ola Harryson, Edward P. Fitts Distinguished Professor of Industrial Systems and Engineers at NC State and corresponding author of the paper adds “… there is no reason this technique could not be used to produce any amorphous alloy. One of the limiting factors at this point is going to be producing or obtaining metal powders of whatever alloy composition you are looking for.”

And even if you did get your hands on the metal powders you’re looking for, desirable results may require some experimentation. “It will take some trial and error to find the alloy compositions that have the best combination of properties for any given application”, Mahbooba continues.

Source: NC State University

(Lead image: Zaynab Mahbooba)

Website: LINK